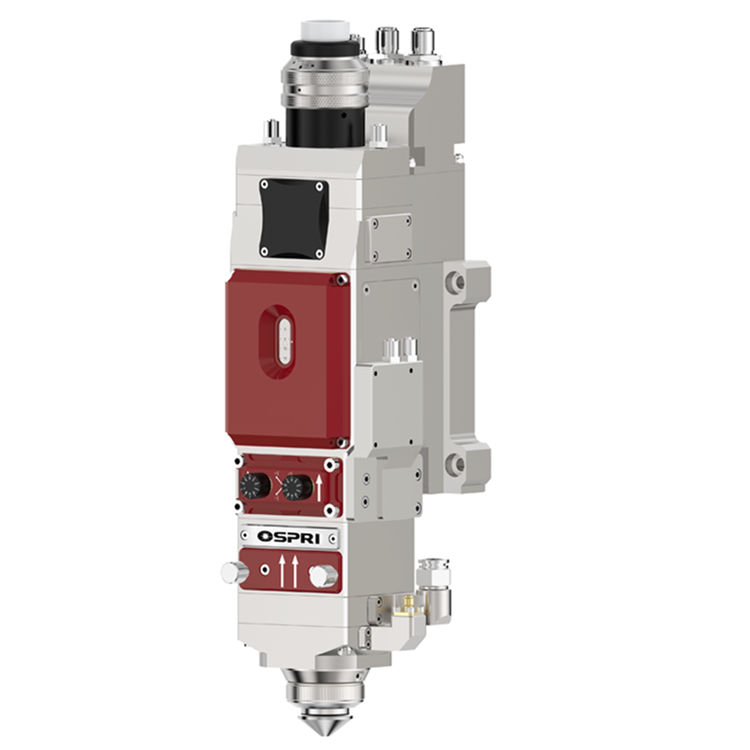

PORAD 10kw PLM500S intelligent focusing fiber cutting head for fiber laser cutting machine

1. Description:

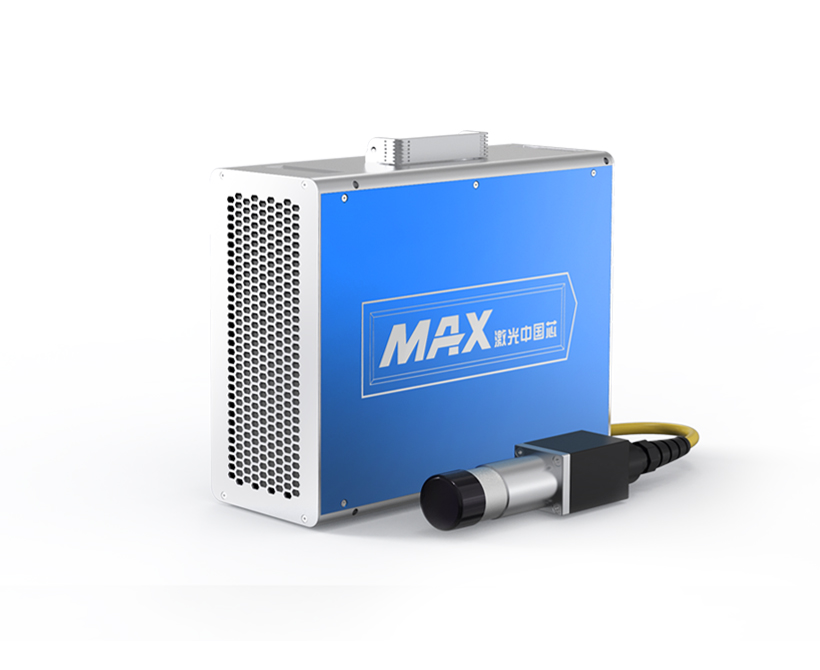

PLM500S is an intelligent focusing fiber cutting head launched by PORAD in the second half of 2018. Diversified interface settings enable it to be matched with various fiber lasers; various sensor data are monitored in real-time on the mobile APP.

2. Technical parameters:

Interface type: QBH, QD

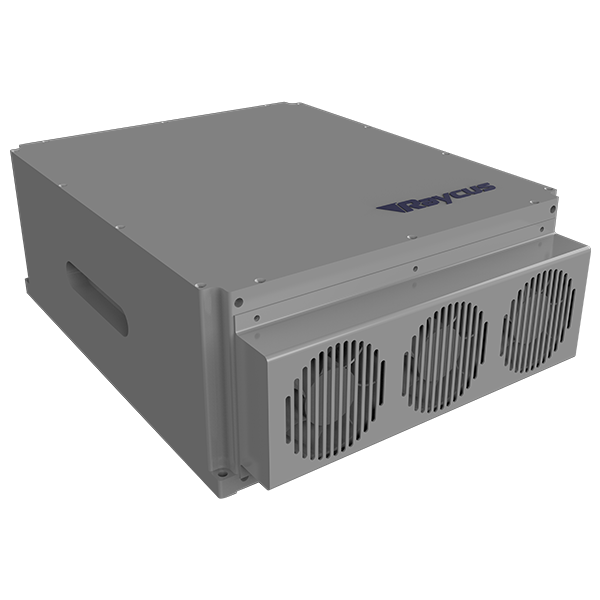

Applicable fiber power: ≤10000W

Focusing lens focal length: 200mm

Focus adjustment range: +15mm~-20mm

Upper protective mirror specification: ø21.5mm*2mm

Lower protective mirror specification: ø37mm*7mm

Auxiliary gas pressure: ≤2.5MPa

3. Feature description:

Diversified fiber optic interface

High degree of dustproof: fully enclosed package optical path.

The internal air pressure and airflow are optimized to make cutting more efficient.

Four LED lights monitor the internal status of the cutting head in real time.

Technological breakthrough of 10,000-watt laser cutting machine

(1) The machine tool matched with the high-power laser must be a high-speed machine tool with high dynamic performance. Higher laser power means faster operating speed and acceleration. The "Lightning Machine Tool" equipped with a 10,000-watt fiber laser generator launched by Pentium Laser, its beam and drive design were re-developed and designed with the support of the Italian SmartCea Center, and the Nastran Sol200 Protocol system was used for simulation analysis. The triangular structure beam is characterized by: the weight is reduced by 30%, the dynamic performance is significantly improved; the maximum moving speed can reach 200m/min, and the dynamic response characteristics of the acceleration is 4g. After the design of the base is updated, the weight is increased by about 20%, and the fixing method of the machine tool is changed to eliminate the impact of high acceleration motion on the impact force of the machine tool.

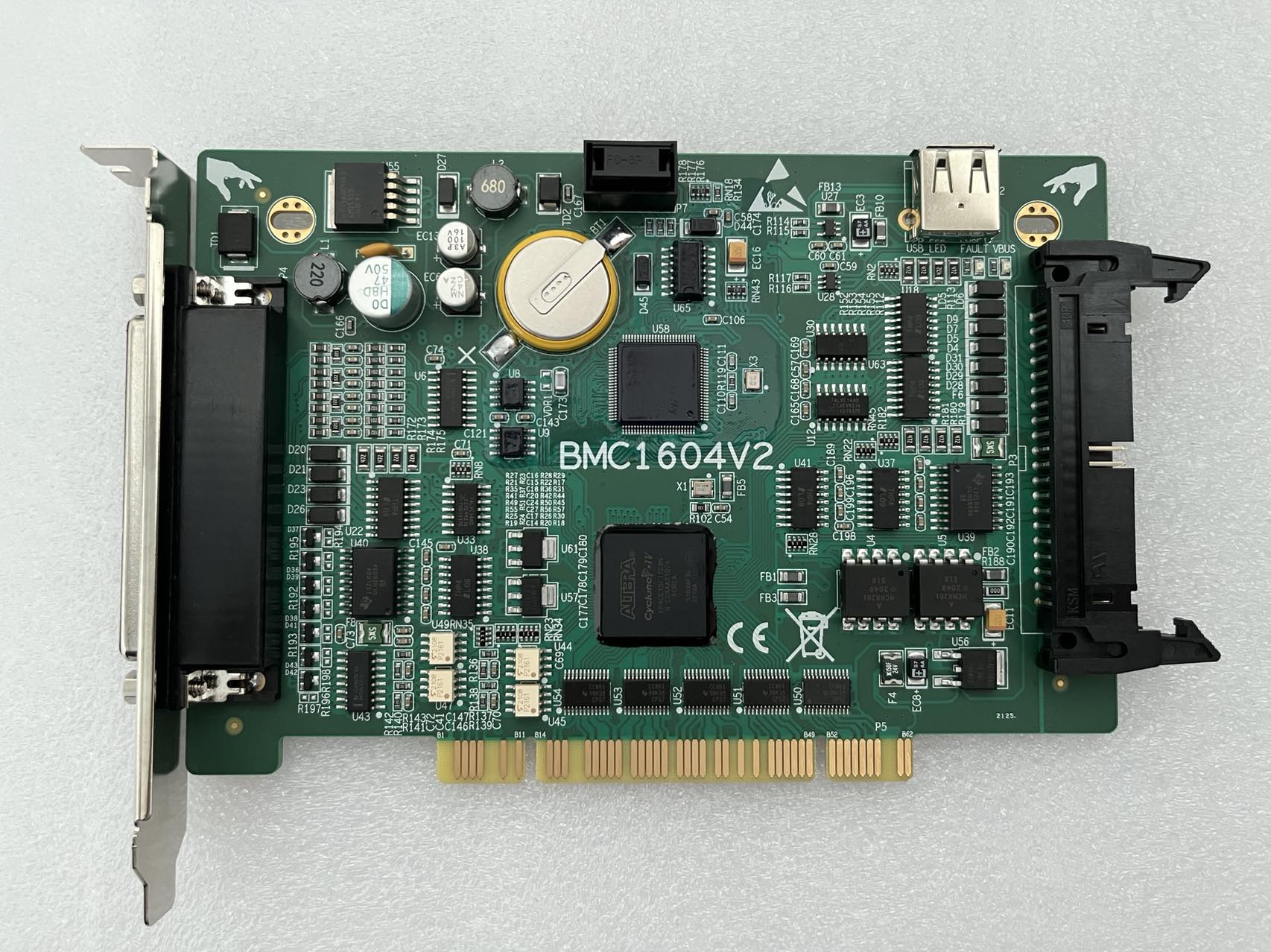

⑵ new software Smart Manager 4.0. The software and control system are like the brain and command center of the machine tool. In addition to the dividends brought by the hardware upgrade, the accuracy and efficiency of the machine tool operation are mainly due to the differences in the software and control systems, and the differences are often huge. In order to cooperate with the application of high-power fiber laser cutting, Pentium Laser currently uses the cutting software version 4.0, which has the following characteristics: stable cutting at a speed of up to 100m/min; the response speed of the capacitive sensor is higher than that of the traditional cutting head The speed of the Z-axis is increased, the operation is smoother without pause, and the thin plate cutting efficiency is increased by more than 25%; the efficiency of the leapfrog function is improved; the acceleration adaptive function is improved; Diagnostic function; intelligent interfaces are reserved for customer enterprises to realize "Industry 4.0".

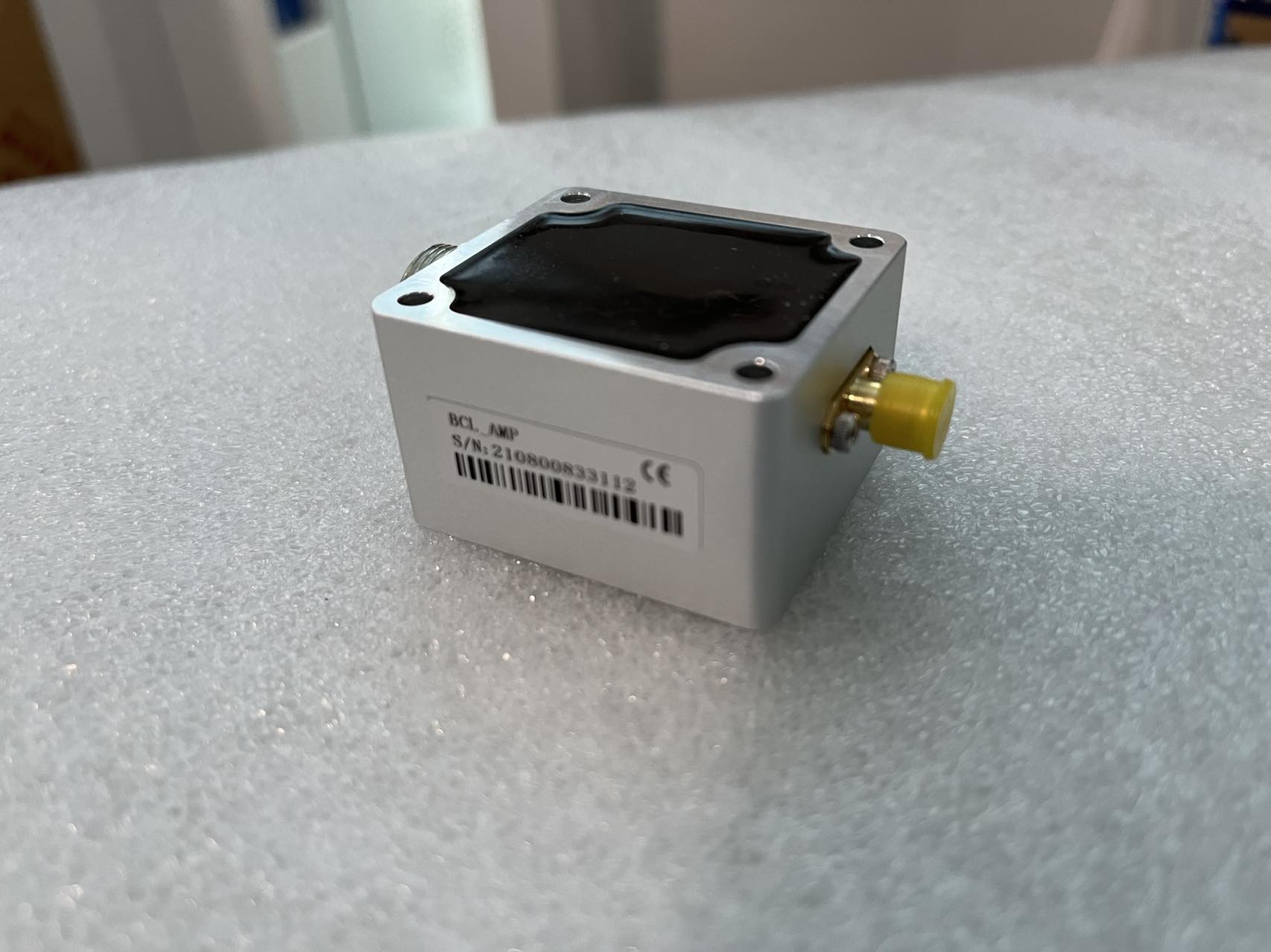

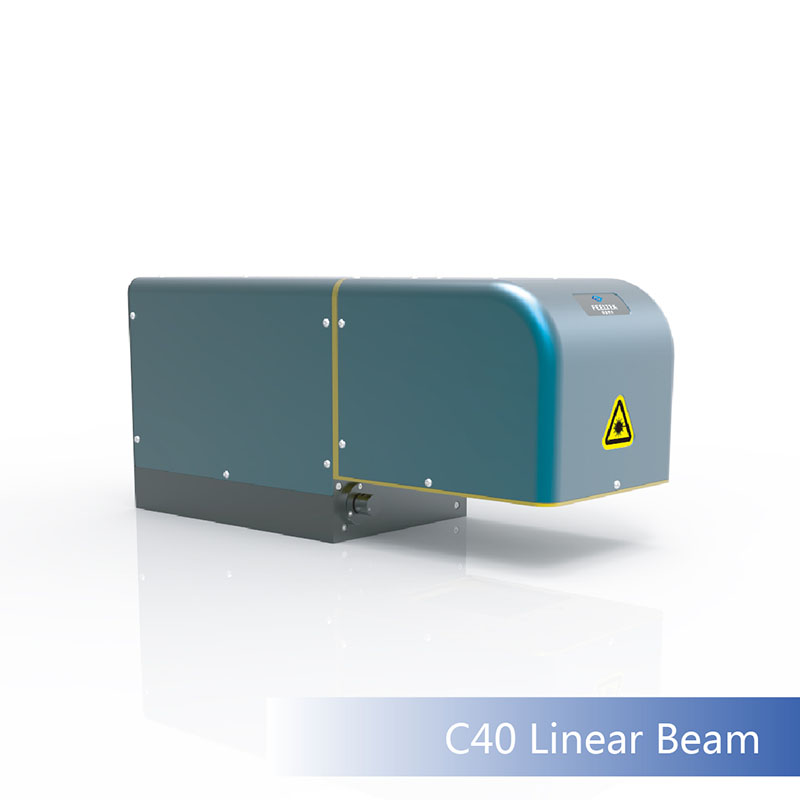

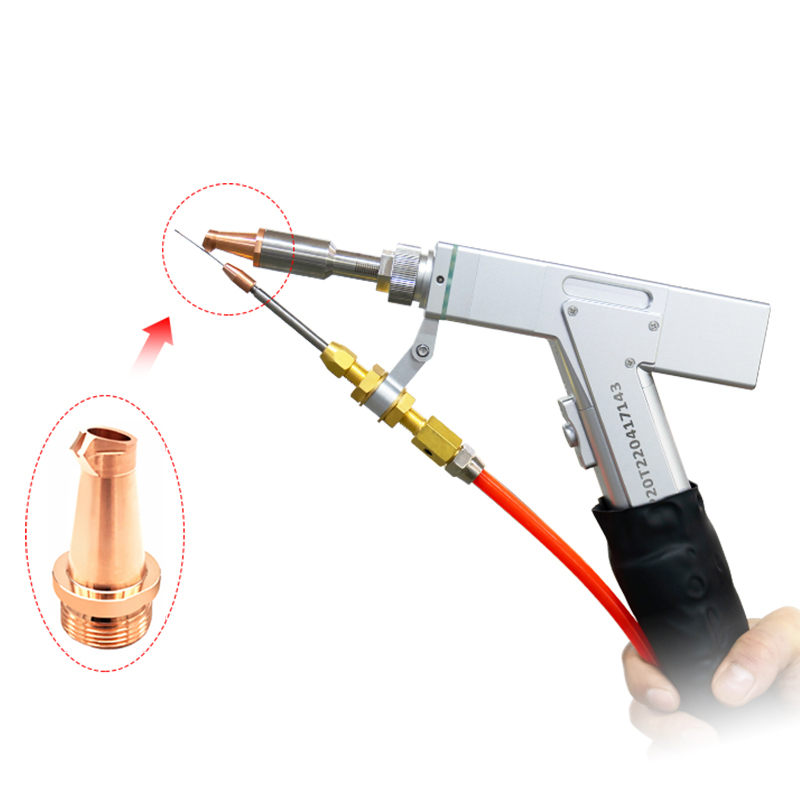

(3) The laser cutting head is the key to long-term stable cutting under high-power continuous operation. Compared with ordinary cutting heads, it requires tighter sealing and more adequate cooling measures, a wider focus range and a higher temperature-resistant coated lens. Due to the high-power thermal lens effect, the beam of the cutting head has a focus drift phenomenon when it works for a long time. Overcoming the focus drift is an important difficulty for high-power laser cutting equipment. The 10,000-watt laser cutting machine uses an updated gas circuit design and The new nozzle improves the cutting speed and cutting stability of thick plates. In addition, safer and more reliable thermal protection of the bed is also a factor that needs to be reconsidered. In addition to the upgrade of software and hardware such as main engine bed and control system, a large number of supporting designs and improvements, as well as more complete cutting technology research are all technical points that high-power laser cutting equipment must overcome.

Changes to the sheet metal processing industry

The first is to improve the thickness range of different sheet metal cutting processes. In the era of CO2 laser cutting, the maximum power of the laser was limited to less than 6000W. The thickness of the early fiber laser cutting sheet was also limited to within 20mm of carbon steel and 12mm of stainless steel. Thicker materials Or traditional processing techniques such as fine plasma, wire cutting or water jet cutting. The first revolutionary change of 10,000-watt fiber laser cutting in the field of sheet metal processing is the continuous improvement of the thickness of different materials (Figure 1): aluminum alloy sheets can reach 40mm, stainless steel sheets can reach 50mm, with 12kW and 15kW With the successive introduction of fiber laser cutting machines, the thickness limit of material cutting will continue to be broken, and the processing price of thick plates will be further reduced, which will trigger more laser cutting applications in the field of thick plates, such as shipbuilding, nuclear power, and national defense. This forms a virtuous circle, which results in the further expansion of the application fields of laser cutting.

What is laser cutting head?

Can a laser cut a human?

How much does a laser metal cutter cost?

How much does a laser cutter charge per hour?