Laser cutting workshop dust collector:

Laser cutting dust collectors are mainly used in industrial production processes to collect waste, filter and purify air, and perform environmental cleaning. It is widely used in various fields such as textile, chemical industry, machinery, medicine, etc., which can prevent the hazards of some occupational diseases and improve production efficiency.

Application scope of laser cutting dust collector:

1. Vacuum cleaners can be used in machining manufacturing industry: cleaning all kinds of metal chips and dust, especially cast iron processing shows its superiority.

2. The vacuum cleaner can be used in the glass fiber manufacturing industry: to absorb the dust and residues generated by the hardened surface grinding in the manufacture of glass fiber products.

3. The vacuum cleaner can be used in the biopharmaceutical industry: for dust removal and purification in the production workshop.

4. The vacuum cleaner can be used in the food industry: absorb oil fume, moisture and food residues.

5. Vacuum cleaners can be used for food items: used for large-scale grain handling, transportation, dumping, and cleaning.

6. Vacuum cleaners can be used in chemical plants: welding fumes, welding fumes, and the absorption of powdery and granular harmful substances.

7. The vacuum cleaner can be used in thermal power plants: it is used to clean the deposited dust and slag, especially the daily cleaning of the boiler, and the dust removal during regular maintenance.

8. The vacuum cleaner can be used in the microelectronics industry: it is used for dust removal, purification and recovery of shearing materials in the production workshop.

9. The vacuum cleaner can be used in the battery manufacturing industry: it is used for cleaning and waste recycling in the production workshop.

10. The vacuum cleaner can be used in the textile industry: it is used to purify the workshop and absorb the fiber flotation in the air.

11. The vacuum cleaner can be used in the foundry industry: it is used to clean the slag and scrap metal blocks in the pouring pit and the pit in front of the furnace; remove the waste sand, metal burrs, and iron oxide scales produced in the casting process; clean the sludge.

12. Vacuum cleaners can be used in cement plants: Cement plants are used for cleaning, loading and unloading, and suction of intermediate products of raw materials to avoid secondary pollution. Especially in the process of cement packaging, dust absorption and cleaning work are generated to improve the working environment of workers.

13. Vacuum cleaners can be used in steel plants: steelmaking, ironmaking, coking, sintering plants, workshops and equipment conveyor belts, transfer stations, high-rise platforms, vehicles, and rolling mill surface cleaning; reduce downtime and improve production efficiency.

14. The vacuum cleaner can be used in the manufacture of automobiles and ships: it is used for the removal of internal welding slag, dust and dirt, and for grinding and dust removal before painting.

Product structure

◇ Siemens motor, Ultra-high negative pressure fan;

◇TORAY filter system;

◇ Visual human-machine interface (HMI);

◇ Industrial exterior design;

◇ Self-developed control system:

◇ Supporting EtherCAT bus, Frequency conversion energy-saving control.

| Configuration description |

| model | TODC-8P/12P/18P/24P |

| Controller | Independent R&D |

| HMI | LCD |

| Motor | SIEMENS |

| Backflush valve | Pulse control |

| Filter | TORAY/ SBFEC

TORAY in JAPA/CHINA |

| Protocol | EtherCAT |

| Energy saving(optional) | Inverter control |

| model | TODC-8P | TODC-12P | TODC-18P | TODC-24P |

| Filter cartridge material | TORAY,F9 | TORAY,F9 | TORAY,F9 | TORAY,F9 |

| Number of Filter cartridge | 8 | 12 | 18 | 24 |

| Air volume | 7000m3/h | 8000m3/h | 12000m3/h | 16000m3/h |

| Air pressure | - | - | - | - |

| Filtration efficiency | 99.99% | 99.99% | 99.99% | 99.99% |

| Filtering area | 160M2 | 240M2 | 360M2 | 480M2 |

| Entrifugal fan | 11KW SIEMENS | 15KW SIEMENS | 18.5KW SIEMENS | 22KW SIEMENS |

| Collector capacity | 90L | 120L | 120L | 120L |

| Air inlet | 400mm(Or Customized ) | 500mm(Or Customized ) | 550mm(Or Customized ) | 600mm(Or Customized ) |

| Power requirments | THREE-PHASE FIVE-WIRE,380V | THREE-PHASE FIVE-WIRE,380V | THREE-PHASE FIVE-WIRE,380V | THREE-PHASE FIVE-WIRE,380V |

| Air pressure request | 0.6MP, compressed air without oil and water | 0.6MP, compressed air without oil and water | 0.6MP, compressed air without oil and water | 0.6MP, compressed air without oil and water |

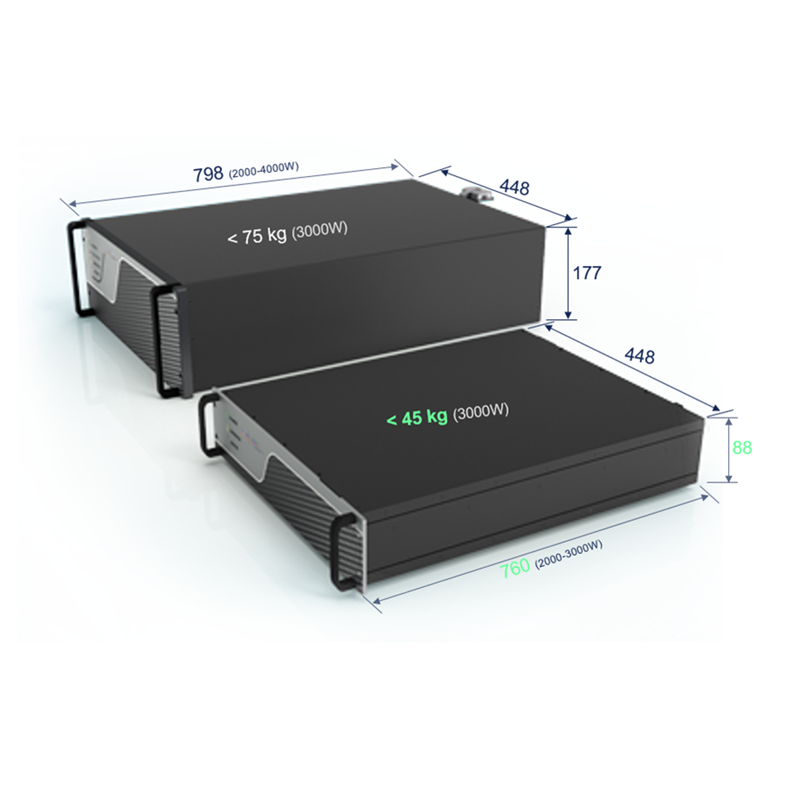

| Unit weight | 1200KG | 1500KG | 1700KG | 1900KG |

| Outline Dimension(mm) | A:2575,B:2215,

C:1016,D:450 | A:2751,B:2215,

C:1516,D:550 | A:3293,B:2215,

C:1516,D:600 | A:3750,B:2215,

C:1516,D:650 |