Maxphotonics Q-Switched Pulse Fiber Laser Sources for Marking Machine 100W-200W MFP-100W

100W-200W Q-SWITCH PULSED FIBER LASER-Leaflet.pdf

100W-200W Q-SWITCH PULSED FIBER LASER-Leaflet.pdf

100W-200W Q-SWITCH PULSED FIBER LASER

Product Description:

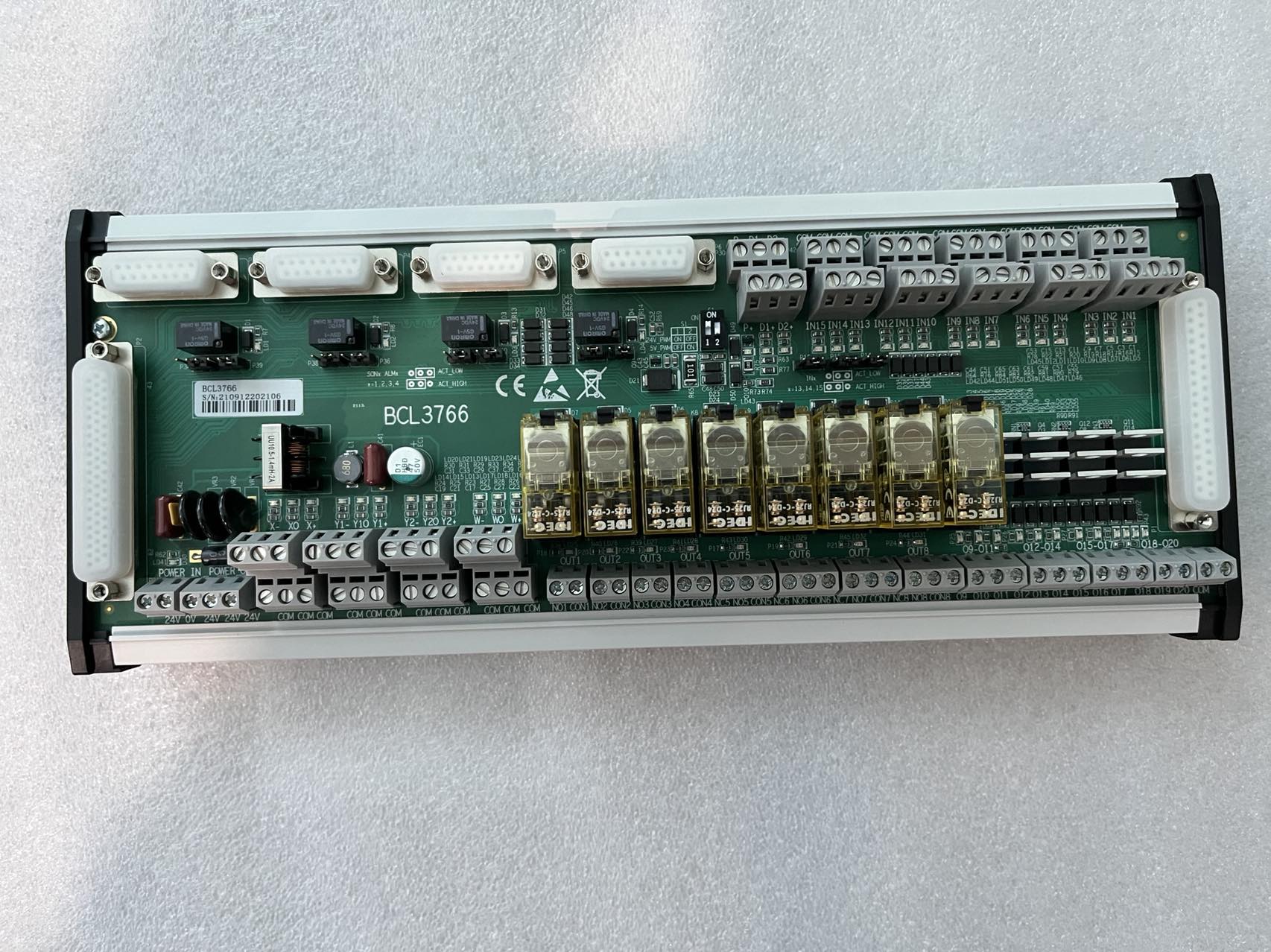

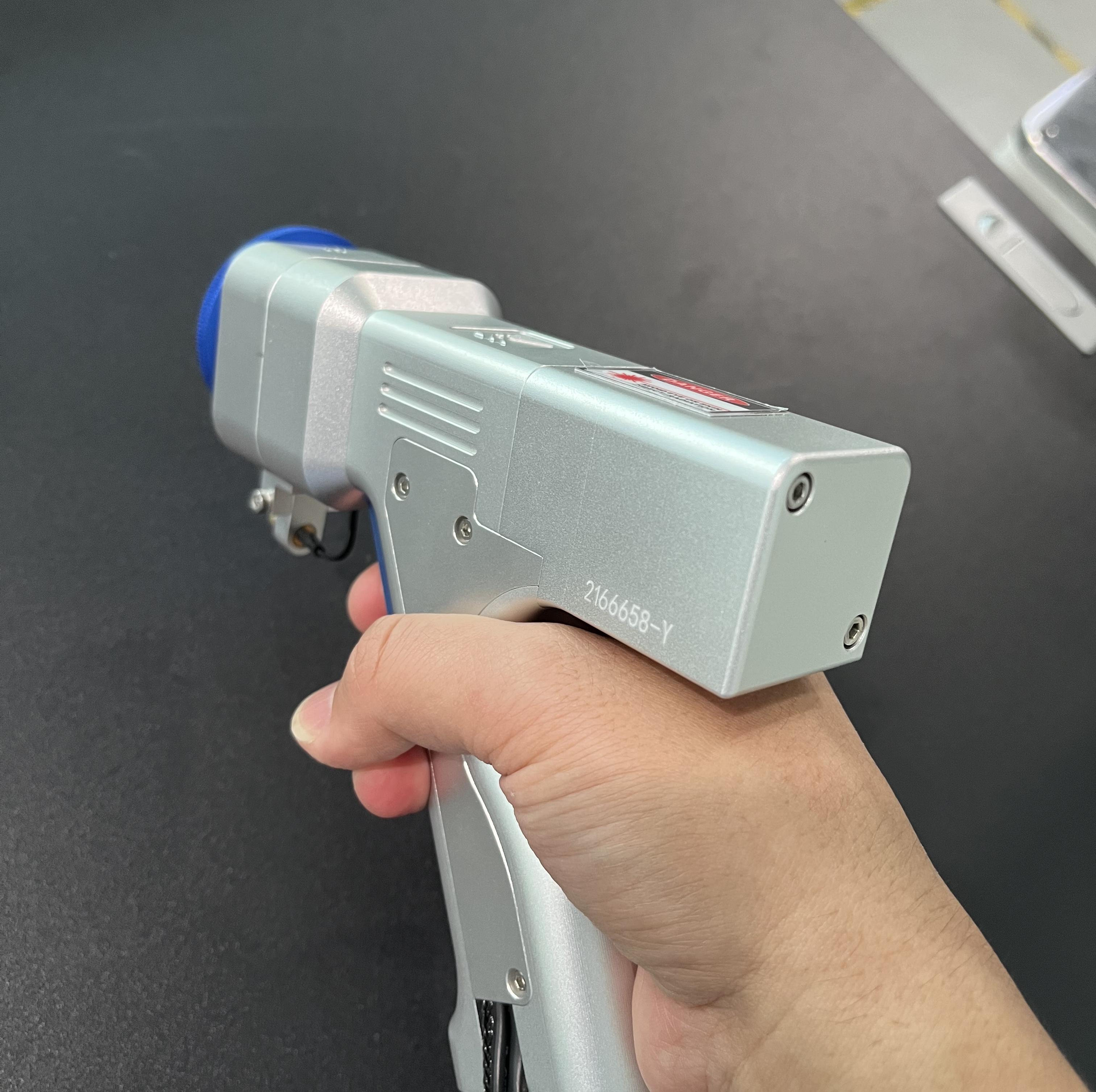

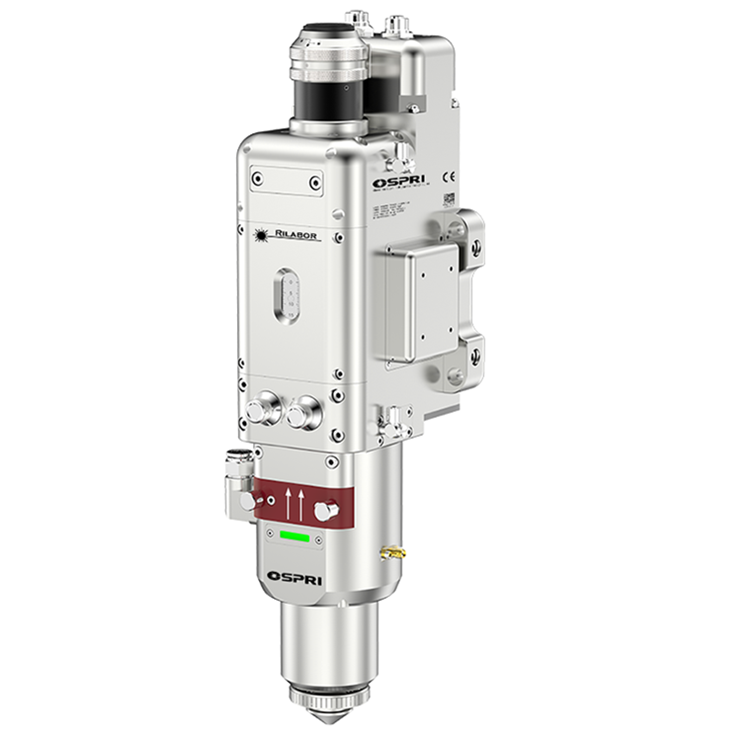

Q-Switch Pulsed Fiber Laser (MFP 100W-200W) Series are maintenance-free fiber lasers based on the Q-switch technology and MOPA. These lasers deliver light whose emission wavelength is centered at 1060nm and peak power is up to 10KW or above. The light is guided to the work piece via a flexible metal-sheathed fiber cable. The laser’s running parameters are set by the user’s special controller via a DB-25 interface.

-

Excellent Single Pulse Energy

Higher single pulse energy makes our laser applicable to more types of materials and applications

-

New Compact and Rugged Design

>40% reduction in volume

Higher flexibility when integrated into system

-

Wide Application Even with Highly Reflective Material

High performance isolator effectively reduces reflection damage to the laser source

Smoothly marking on aluminum, copper and brass etc.

-

High Level Vertical Integration

All key components are designed and produced in house

Strict quality control, high consistency and reliability

Sample Show:

Sample Show

Stainless Steel Deep Engraving

Communication jumper / cable / optical cable marking

Sheet Metal Processing

Cutting and welding of steel plates and tubes

Laser cutting of construction iron frames, cutting of doors and windows, cleaning of rust on iron frames, welding of iron frames

Laser cleaning of ships, laser cutting / welding of hulls

Sink / faucet / kitchenware stainless steel cutting and welding,Kitchenware panel character / graphic marking

Rings / necklaces / gold cutting, marking characters / patterns

Cutting and welding of metal billboards / advertising stands. Advertising character marking

Character marking for accessories such as mobile phones / tablets / computers and charging heads, internal antenna / middle board / camera welding. Volume hole perforation

The laser illuminates the object, and the internal structure emits changes. Laser irradiation promotes physical / chemical reactions of materials, laser fusion

Marking with forceps and scalpel,Medical equipment parts welding

Auto paint laser cleaning, repainting, car body welding, car body cutting, car interior control interface / button marking

Power battery tab cutting / welding, battery shell / pole / explosion valve welding

Laser scribing of solar panels

Flying marking of cans / plastic food packaging. Flying marking of plastic bottle

Chip number marking, chip scribing, laser trimming

Dial / back cover character / graphic marking, watch hands / gear / cutting

Fine marking / scribing of semiconductor device

Product Parameters:

| Models | MFP-100W | MFP-200W |

| OPTICAL SPECIFICATIONS |

| Nominal Power | 100W | 200W |

| Mode of Operation | Pulsed |

| Polarization | Random |

| Power Tunability | 5 to 100% |

| Wavelength | 1064 ± 5 nm |

| Power Stability | ≤5 % |

| Laser Beam Quality M² | ≤2 @1.5 mJ |

| Pulse Energy | 1.5~8 mJ |

| Pulse Duration | 150~190 ns | 180~220 ns |

| Repetition Rate | 20~200 kHz | 30~200 kHz |

| Full Power Repetition Rate | 15 @6.7 mJ | 30 @6.7 mJ |

| FIBER DELIVERY SYSTEM |

| Length | 5m standard, other lengths optional |

| Beam Diameter | 5~9 mm |

| Beam Ellipticity | 90% |

| ELECTRICAL RATINGS |

| Supply Voltage | 220 VAC Single-phase |

| OTHER SPECIFICATIONS |

| Operating Temperature | +10 to +35℃ |

| Storage Temperature | -10 to +60℃ |

| Humidity | 10 to 95% |

| Cooling Method | Air Cooling |

| Dimension | 540.4×482.6×131.3 mm |

| Weight | 21 kg |